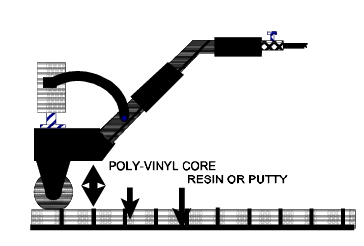

| Vibrating rollers for PVC core construction.

2″ x 6” Plastic roller with a slight radius to evenly apply vibrating force as the core flexes during construction. Other roller radius available upon request. Low (5.6CFM) air consumption. Decreases bonding time for all PVC core construction, with or without bonding putty. Model VS1250 for 1/2” core and or bonding putty. Model VS750 for ,1/2”. Rollers w/45″ and 30” Radius available. Air Cushioned vpiston vibrator for reduced noise. |

|

Model VS750

Assists poly-vinyl core material bond through out molecular friction generated by the high frequency of the ¾” piston. At 12,500 cycles per minute, heat is generated, causing acceleration in the catalyzation process. This reduces voids caused by the de-lamination that happens in countered surfaces. Model VS1250 This vibrator is used for cores above ½” thickness and/or when a heavy viscosity bonding putty is used. The model 1250 has a 1 ¼ “piston that forces the bonding putty into the core material. Model VS750 & VS1250 60” Radius ultra high molecular weight roller head applies even force to the complete 6” roller section. Bronze bushings are used for long life. Roller is mounted to a 3/8” steel shaft that cannot vibrate loose. Both units are an excellent choice when vacuum bagging is not feasible. |